Think the trades are all hammers, hard hats, and heavy lifting?

Think again.

A quiet revolution is underway on construction sites around the world, driven by robotics and artificial intelligence (AI). And it’s giving rise to a brand-new role that barely existed a few years ago: the Construction Robotics Operator.

This isn’t science fiction. It’s already happening, and it could transform what it means to work in the skilled trades.

Robots Are Coming to the Jobsite—But They Need People

Let’s clear up a common misconception: robots are not taking over construction sites on their own.

Yes, machines like layout robots, bricklaying robots, and autonomous equipment are becoming more common. But they still need skilled humans to set them up, operate them, and troubleshoot when things go wrong.

That’s where the Construction Robotics Operator comes in.

So… What Does a Construction Robotics Operator Actually Do?

In simple terms, they’re the bridge between traditional skilled trades and the new digital tools reshaping the jobsite.

Depending on the robot or system, their job might include:

- Uploading digital plans into robots for layout work

- Calibrating and positioning robotic equipment on site

- Monitoring machine performance to ensure accurate results

- Troubleshooting technical errors if the robot hits a snag

- Maintaining robotics equipment to keep it running smoothly

- Coordinating with crews to ensure robotic work integrates seamlessly into the larger project

In short: they’re part technician, part tradesperson, part digital problem-solver.

Where Are These Jobs Appearing?

Here are just a few examples of where Construction Robotics Operators are already in action:

1. Layout Robots

Companies like Dusty Robotics have developed robots that print precise floor layouts directly onto concrete slabs. Instead of pulling tape measures and chalk lines, operators load digital plans into the robot and oversee its movements.

Why it matters: Layout mistakes cause costly rework. Robots increase accuracy, but a human must supervise and verify the robot’s work.

2. Bricklaying Robots

Robots like the SAM100 (Semi-Automated Mason) can lay bricks faster than a human. But operators still:

- Adjust mortar consistency

- Program patterns

- Handle finishing touches

Why it matters: SAM isn’t replacing masons, it’s a tool masons operate to boost productivity.

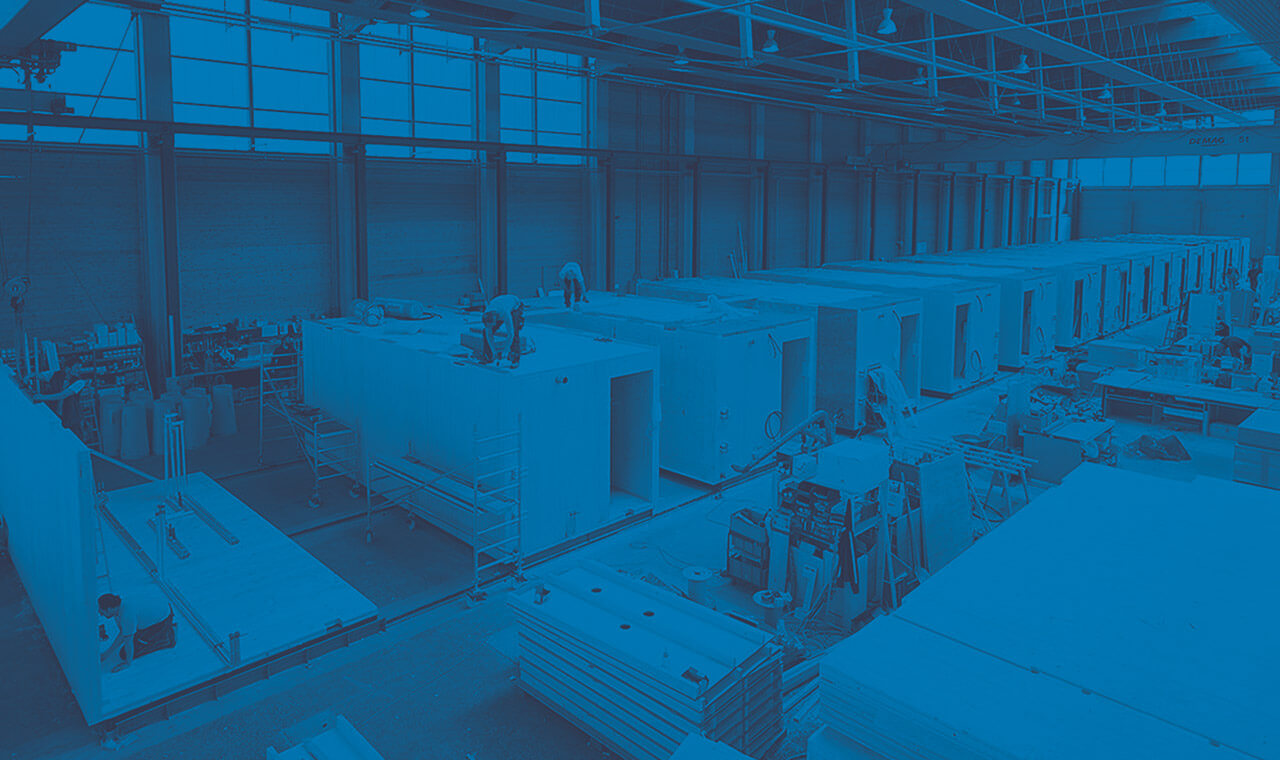

3. Robotic Welding and Cutting

In prefabrication shops and modular factories, robotic arms perform repetitive welding and cutting tasks. Operators:

- Set welding parameters

- Monitor quality

- Perform maintenance

Why it matters: Skilled welders don’t disappear, they become robotic welding specialists.

4. Autonomous Equipment

Bulldozers, excavators, and loaders are increasingly semi-autonomous. Operators:

- Program routes or cuts

- Supervise work

- Step in for fine tasks robots can’t handle

Why it matters: It’s still heavy equipment operation, but with new digital layers.

Why This Job Matters for the Future of Construction

Construction faces major challenges:

✅ Skilled labor shortages

✅ Demands for higher productivity

✅ Pressure to deliver projects faster and safer

Robotics helps fill gaps, but only if people know how to work with them.

Construction Robotics Operators are crucial because:

- They keep robots running. No robot works without human oversight.

- They bridge traditional skills and technology. Operators often come from the trades and learn new digital skills.

- They protect quality. Robots help with precision, but people ensure the final product meets standards.

New Skills for the Modern Tradesperson

Becoming a robotics operator doesn’t mean abandoning traditional skills. Instead, it requires:

🔧 Mechanical know-how → Understanding tools, equipment, and materials

💻 Digital literacy → Comfort with computers, software, and digital plans

🧠 Problem-solving skills → Troubleshooting when robots hit snags

📊 Data interpretation → Reading dashboards, measurements, and reports

A New Path for the Next Generation

Here’s the exciting part: these jobs often pay well, combine physical work with technology, and offer future-proof careers.

For young people who love working with their hands and technology, becoming a Construction Robotics Operator could be an incredible path. It’s a chance to stay connected to the trades while riding the wave of the industry’s digital transformation.

So… Will Robots Replace the Trades?

Not anytime soon.

Instead, robots are becoming new tools in the tradesperson’s toolbox. And skilled people will always be needed to guide, operate, and oversee them.

The trades of tomorrow will still require craftsmanship, judgment, and problem-solving, but paired with digital skills and robotics know-how. That’s why Construction Robotics Operator might just be the trade of the future.

Want to Learn More?

At Jib, we’re tracking how technology is reshaping construction and the skilled trades. Let’s talk about how your business can prepare for the next generation of work.

Wondering how storytelling and smart marketing can advance offsite construction, mass timber, and sustainability in North America?

Whether you’re in AEC, sustainability, or shaping the built environment, we’d love to connect. Let’s talk – or explore BuildBetter.Marketing.

Structure needs story. Jib delivers.